No 1255, Xingye Road, Tianzihu Modern Industrial Park, Anji County, Zhejiang Province, China

The **upholstered dining chairs with metal legs** segment requires meticulous engineering due to the concentrated stress applied at the junction between two disparate materials: the upholstered seat structure and the rigid metal legs. For B2B buyers, verifying the chair's structural soundness involves scrutinizing the joint design and demanding certified compliance with industry standards for load bearing, which ensures the Structural integrity of metal leg dining chairs over years of high-frequency use.

Four Metal Legs Steel Frame Upholstered Armless Fabric Swivel Dining Chair

The connection where the metal leg meets the seat frame is the primary point of structural failure. The correct Metal leg to seat frame joint design is essential for longevity.

The joint must manage complex forces—vertical compression, lateral sway (racking), and cantilevered stresses from leaning back. Effective reinforcement often involves using corner gussets, cross-bracing, or employing a full sub-frame within the seat box to distribute the load from the leg connections across a wider area of the seat structure.

| Joint Type | Relative Structural Integrity | Assembly Complexity | Primary Failure Mode |

|---|---|---|---|

| Permanent Weld | Highest (Essential for high Structural integrity of metal leg dining chairs). | Low (Factory assembled). | Material fatigue near the Heat-Affected Zone. |

| Bolted/Knock-Down (KD) | Moderate (Requires quality hardware and periodic tightening). | High (Consumer assembly). | Hardware loosening and stripping of threads. |

Compliance with industry load standards is the objective measure of durability. The **upholstered dining chairs with metal legs** must meet both static and dynamic requirements.

Dynamic testing simulates real-world abuse, such as quickly dropping into the chair or tilting. This is crucial for evaluating fatigue resistance, where repeated, lower-magnitude stress is more destructive than a single static overload.

The Business and Institutional Furniture Manufacturers Association (BIFMA) provides globally recognized benchmarks for furniture safety and durability.

The longevity of **upholstered dining chairs with metal legs** is proven through Dynamic durability testing for upholstered chairs. This includes rearward stability testing and cyclic load tests (e.g., BIFMA 11.2, which simulates leaning back repeatedly). These cyclic tests, involving thousands of repetitions, are the definitive measure of fatigue resistance and long-term Structural integrity of metal leg dining chairs.

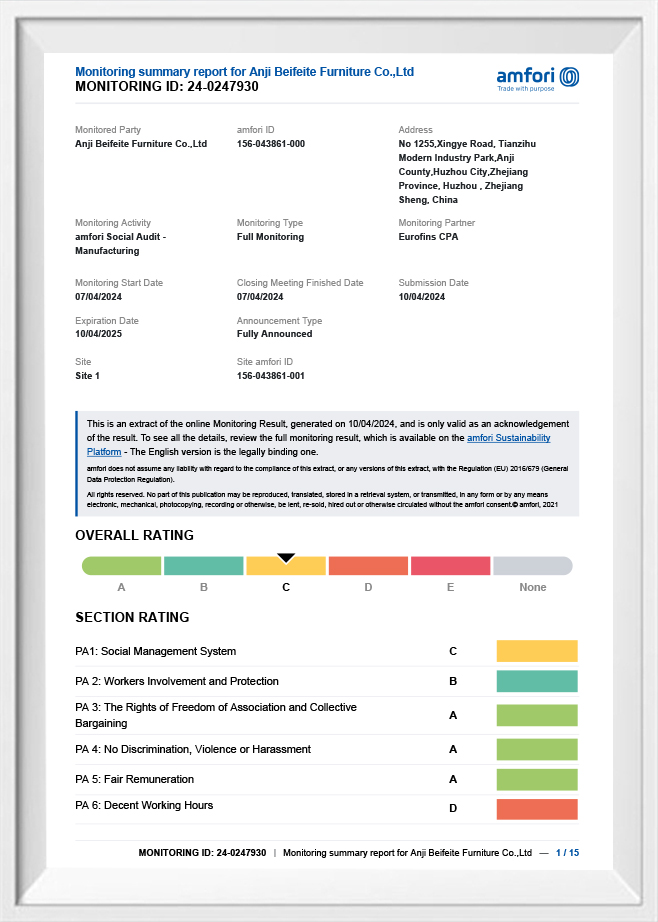

Anji Beifeite Furniture Co., Ltd., founded in 2017 in China Chair Town—Anji, is a large-scale professional furniture manufacturer specializing in metal chairs, dining chairs, and bar stools. We understand that the durability of **upholstered dining chairs with metal legs** is critical for commercial success. Our 60,000 square meter factory is equipped with advanced production equipment to ensure high manufacturing precision, allowing us to meet strict requirements for Minimum weight capacity for commercial dining chairs. Our engineering team meticulously designs the **Metal leg to seat frame joint design** and validates structural integrity through continuous testing, adhering to and often exceeding BIFMA standards for dining chair static load. Our eternal tenet is the best quality and service to satisfy our customers, welcoming new and old partners to contact us for mutual success.

Dynamic testing focuses on fatigue resistance and simulating real-world abuse, such as repeated rocking or impact. It verifies that the chair can endure thousands of load cycles without the structural components failing or becoming permanently loosened.

BIFMA standards typically require a commercial chair to withstand a static load of 1020 Newtons (equivalent to approximately 225 lbs) applied to the seat for a specified duration.

The joint is critical because it connects two materials with different stiffness and damping properties (rigid metal and flexible upholstered frame). This requires specialized design, welding, or high-grade bolting to manage the concentrated stress at the interface.

A permanently welded joint provides the highest long-term structural integrity by creating a monocoque structure, eliminating the risk of screws or bolts loosening over time from repeated movement and vibration.

Buyers should primarily reference ANSI/BIFMA X5.1, as it defines the accepted safety and durability criteria for institutional and commercial seating in the North American market, which is widely adopted globally.